The Evolution of Battery Technology in Modern Industries

The landscape of industrial power solutions has undergone a remarkable transformation with cylindrical lithium batteries emerging as the cornerstone of safe and reliable energy storage. These sophisticated power cells have revolutionized how industries approach their energy needs, offering an optimal balance of safety, performance, and longevity. As businesses increasingly prioritize sustainable and secure power solutions, cylindrical lithium batteries have become the gold standard across diverse sectors, from automotive to aerospace.

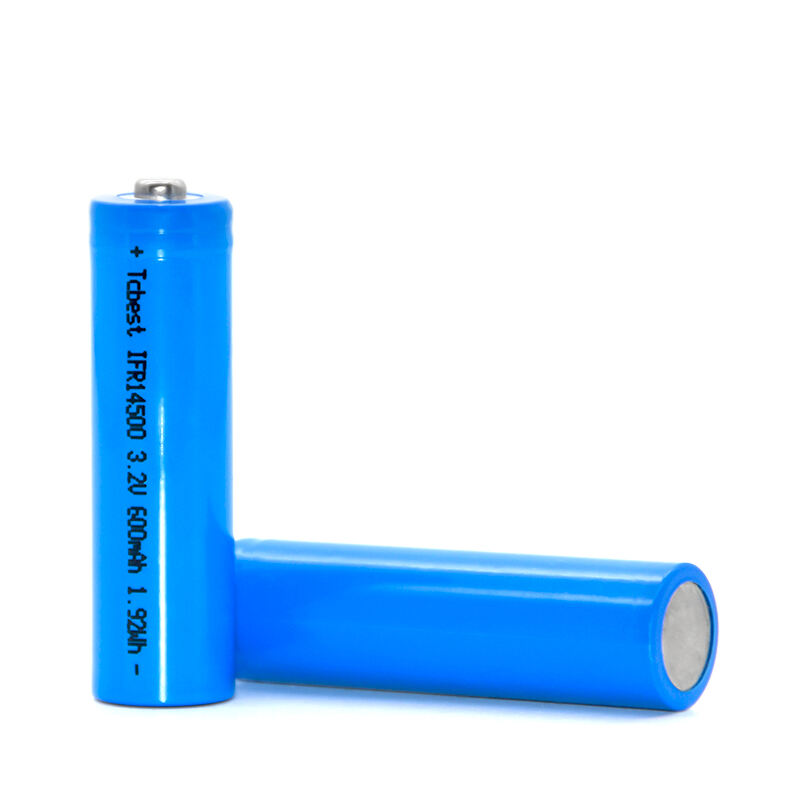

The industrial adoption of cylindrical lithium batteries represents a significant shift from traditional power sources, driven by their inherent safety features and remarkable versatility. These batteries have proven themselves in demanding applications where reliability and safety cannot be compromised. Their cylindrical design, far from being a mere aesthetic choice, plays a crucial role in their safety profile and performance capabilities.

Advanced Safety Features of Cylindrical Battery Design

Structural Integrity and Pressure Management

The cylindrical form factor of these lithium batteries provides exceptional structural strength, making them highly resistant to physical stress and impact. The design allows for optimal pressure distribution throughout the cell, minimizing the risk of internal damage during operation. When internal pressure builds up due to chemical reactions or temperature changes, the cylindrical shape helps maintain structural integrity better than other battery configurations.

Engineers have incorporated sophisticated pressure relief mechanisms into cylindrical lithium batteries, ensuring controlled venting in rare cases of excessive pressure buildup. This safety feature prevents catastrophic failures and protects both equipment and operators. The robust metal casing acts as an additional safety barrier, containing any potential internal issues.

Thermal Management Excellence

Heat dissipation is crucial for battery safety, and cylindrical lithium batteries excel in this aspect. Their design facilitates efficient heat distribution and cooling, preventing hotspots that could compromise battery integrity. The cylindrical shape provides an optimal surface-area-to-volume ratio, enabling better thermal management compared to other battery formats.

Modern cylindrical lithium batteries incorporate advanced thermal management systems, including specialized coatings and internal structures that enhance heat dissipation. This sophisticated approach to thermal control extends battery life while maintaining safe operating temperatures even under heavy loads.

Industrial Applications and Performance Benefits

Automotive and Electric Vehicle Integration

The automotive industry has embraced cylindrical lithium batteries for their exceptional safety record and consistent performance. Electric vehicle manufacturers rely on these batteries to power their vehicles safely through varying conditions and demanding usage patterns. The cylindrical format allows for flexible pack configurations, enabling designers to optimize space utilization while maintaining robust safety standards.

Leading automotive companies have reported significant improvements in vehicle safety ratings after adopting cylindrical lithium batteries. The standardized form factor facilitates easier quality control and manufacturing processes, resulting in more reliable and safer battery packs for electric vehicles.

Energy Storage and Grid Applications

Large-scale energy storage systems benefit from the modular nature of cylindrical lithium batteries. Grid operators and utility companies choose these batteries for their proven safety track record and scalability. The ability to easily replace individual cells without compromising the entire system makes maintenance more practical and cost-effective.

Industrial energy storage installations utilizing cylindrical lithium batteries have demonstrated exceptional reliability in demanding environments. The standardized form factor simplifies installation and maintenance procedures while ensuring consistent performance across large-scale deployments.

Quality Control and Manufacturing Standards

Rigorous Testing Protocols

Manufacturers subject cylindrical lithium batteries to extensive testing procedures to ensure safety and reliability. These tests include thermal cycling, mechanical stress testing, and electrical performance verification. The standardized shape of cylindrical cells allows for consistent and thorough testing methodologies across production batches.

Quality control measures extend beyond basic safety testing to include advanced diagnostic procedures that verify the internal construction and chemical composition of each cell. This comprehensive approach to quality assurance has contributed to the excellent safety record of cylindrical lithium batteries in industrial applications.

Manufacturing Excellence and Automation

The production of cylindrical lithium batteries benefits from highly automated manufacturing processes that ensure consistency and quality. Advanced robotics and precision equipment handle critical assembly steps, minimizing human error and maintaining strict quality standards. The cylindrical format lends itself well to automated production lines, resulting in more reliable and safer products.

Modern manufacturing facilities employ sophisticated monitoring systems that track every aspect of the production process. This level of oversight helps maintain the highest safety standards while enabling continuous improvement in manufacturing techniques.

Future Developments and Safety Innovations

Advanced Materials and Design Improvements

Research continues to advance the safety features of cylindrical lithium batteries through innovative materials and design improvements. Scientists are developing new electrode materials and electrolyte formulations that enhance both safety and performance. These advancements promise to further reduce the already minimal risks associated with cylindrical lithium batteries.

The integration of smart monitoring systems and advanced battery management technologies is revolutionizing how industries monitor and maintain their battery systems. These innovations provide real-time safety monitoring and predictive maintenance capabilities, further enhancing the safety profile of cylindrical lithium batteries.

Regulatory Compliance and Industry Standards

The development of cylindrical lithium batteries continues to be guided by evolving safety standards and regulations. Industry bodies and regulatory authorities work closely with manufacturers to establish and update safety guidelines, ensuring that new developments maintain the highest safety standards. This collaborative approach helps drive continuous improvement in battery safety technology.

As global safety standards become more stringent, the inherent safety advantages of cylindrical lithium batteries position them well for future regulatory requirements. Their proven track record and ongoing safety innovations make them a future-proof choice for industries investing in sustainable power solutions.

Frequently Asked Questions

What makes cylindrical lithium batteries safer than other battery formats?

Cylindrical lithium batteries offer superior safety due to their robust structural design, efficient pressure management systems, and excellent thermal dissipation capabilities. The cylindrical shape provides inherent strength against physical stress while facilitating even heat distribution, making them less prone to thermal runaway and other safety issues.

How long do cylindrical lithium batteries typically last in industrial applications?

The lifespan of cylindrical lithium batteries in industrial applications typically ranges from 8 to 12 years, depending on usage patterns and environmental conditions. With proper maintenance and operating conditions, these batteries can maintain over 80% of their original capacity throughout their service life.

Can cylindrical lithium batteries be safely recycled?

Yes, cylindrical lithium batteries are designed with recycling in mind. Their standardized format and construction make them ideal for established recycling processes. Specialized facilities can safely recover valuable materials like lithium, cobalt, and nickel, contributing to a sustainable circular economy.