1. The Capacity Fallacy in Battery Evaluation

The widespread assumption that “greater capacity equates to a superior battery” appears intuitively plausible. A battery capable of storing more energy ostensibly promises extended operating time, enhanced endurance, and reduced interruption—attributes highly valued across consumer electronics, unmanned aerial vehicles (UAVs), robotics, and electric vehicles. Yet, when examined through the lens of real-world engineering practice—particularly under conditions involving dynamic load profiles, stringent thermal constraints, long-term reliability requirements, and safety-critical environments—it becomes evident that capacity represents only one dimension of battery performance. A cell advertised with exceptionally high milliamp-hour (mAh) or watt-hour (Wh) ratings may nonetheless exhibit mediocre functional behavior, accelerated degradation, or even elevated safety risks if other essential parameters are inadequately engineered.

2. Understanding Capacity and Its Practical Limitations

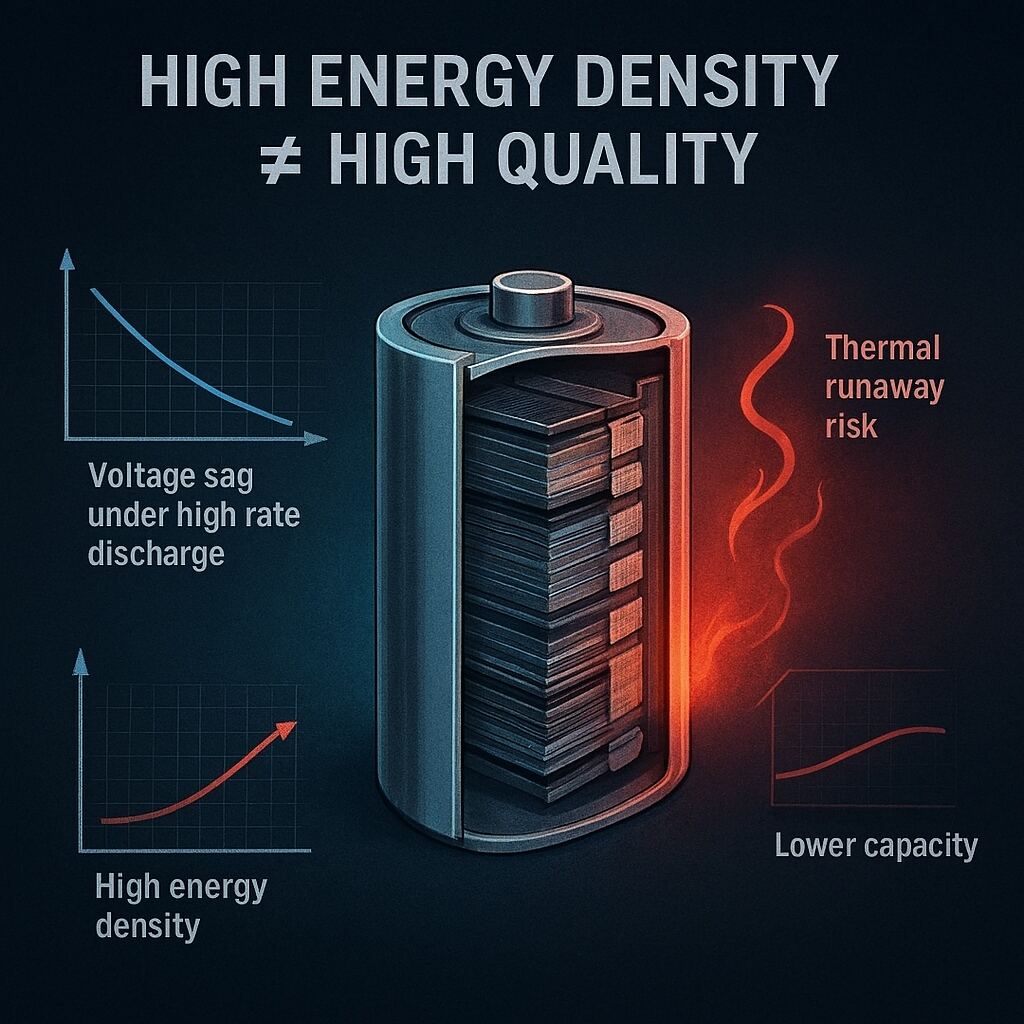

A rigorous understanding of this issue requires clarifying the definition and limitations of capacity. Battery capacity, typically expressed in mAh, Ah, or Wh, quantifies the amount of charge or energy a cell can store. However, these values are derived under standardized laboratory conditions—low discharge rates, controlled temperature, and benign load curves—that diverge substantially from the operational environments of most devices. In practical applications, high-rate discharge induces voltage sag, internal heat generation, and electrochemical polarization, all of which diminish the usable capacity. Similarly, over the battery’s lifetime, factors such as elevated temperature, deep cycling, high-rate charging and discharging, and mechanical stress progressively degrade active materials, accelerating capacity fade. Many high-capacity cells achieve their energy density by employing thinner electrodes or more aggressive chemistries, which often compromise structural robustness and thermal stability. Consequently, after several hundred cycles, such cells may perform worse than lower-capacity counterparts designed with more conservative and durable architectures.

3. Engineering Trade-Offs Behind High Energy Density

Moreover, the pursuit of high capacity inherently involves complex engineering trade-offs. Increasing energy density typically requires incorporating more active material, which in turn necessitates thinner separators and more compact internal structures. While these design choices improve gravimetric and volumetric energy density, they also heighten susceptibility to thermal runaway, particularly under high-current operation or abusive conditions. This trade-off explains why sectors such as aviation, medical devices, and industrial robotics frequently adopt lithium iron phosphate (LiFePO₄) chemistries, which offer lower capacity but superior thermal stability and cycle life. Energy-oriented chemistries such as NCM and NCA, although capable of high capacity, often exhibit limited discharge rates and elevated internal resistance, rendering them less suitable for applications requiring rapid power delivery. In contrast, power-optimized cells sacrifice some capacity to achieve stable voltage output, low impedance, and strong transient response—characteristics essential for UAVs, where both burst power and lightweight design are critical. It is also important to recognize that increasing capacity generally increases mass and volume, which may reduce overall system efficiency in weight-sensitive platforms, thereby negating the theoretical benefits of higher energy storage.

4. A Multidimensional Framework for Battery Quality

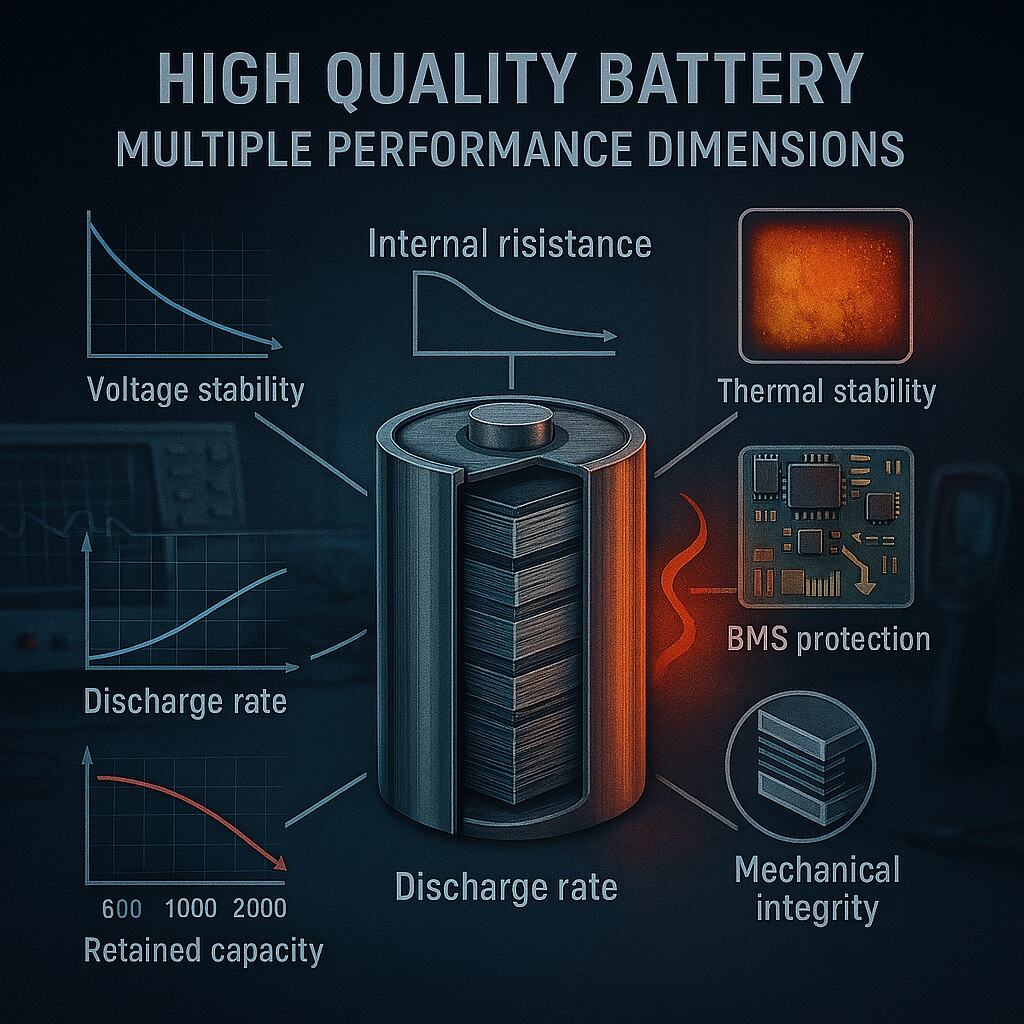

Defining a “high-quality” battery therefore requires a multidimensional evaluation framework. Internal resistance is a foundational metric, influencing voltage stability under load, thermal behavior, and effective energy utilization. A high-capacity cell with elevated internal resistance may deliver inferior real-world performance. Discharge capability, typically expressed as C-rate, determines whether a battery can sustain peak loads without voltage collapse, overheating, or accelerated aging. For UAVs, which frequently undergo rapid acceleration and hovering, continuous discharge capabilities in the range of 10C to 30C are often more consequential than nominal capacity. Cycle life is another critical dimension: retaining 80% of initial capacity after 500 cycles is generally considered acceptable, 1000 cycles excellent, and beyond 2000 cycles indicative of industrial-grade durability. Many high-density cells do not excel in this regard. Thermal stability is central to safety; a high-quality battery must maintain safe temperature rise under heavy load, fast charging, or high-ambient-temperature conditions to avoid initiating thermal runaway. At the pack level, a robust Battery Management System (BMS) is indispensable, providing accurate cell balancing, short-circuit protection, and overcharge/over-discharge/over-temperature safeguards. Without such protections, even high-performance cells may pose significant hazards. Mechanical integrity—reinforced tabs, multilayer protective films, corrosion-resistant electrolytes, and high-quality sealing—further determines long-term reliability under vibration, impact, and thermal cycling.

5. Application-Specific Performance Considerations

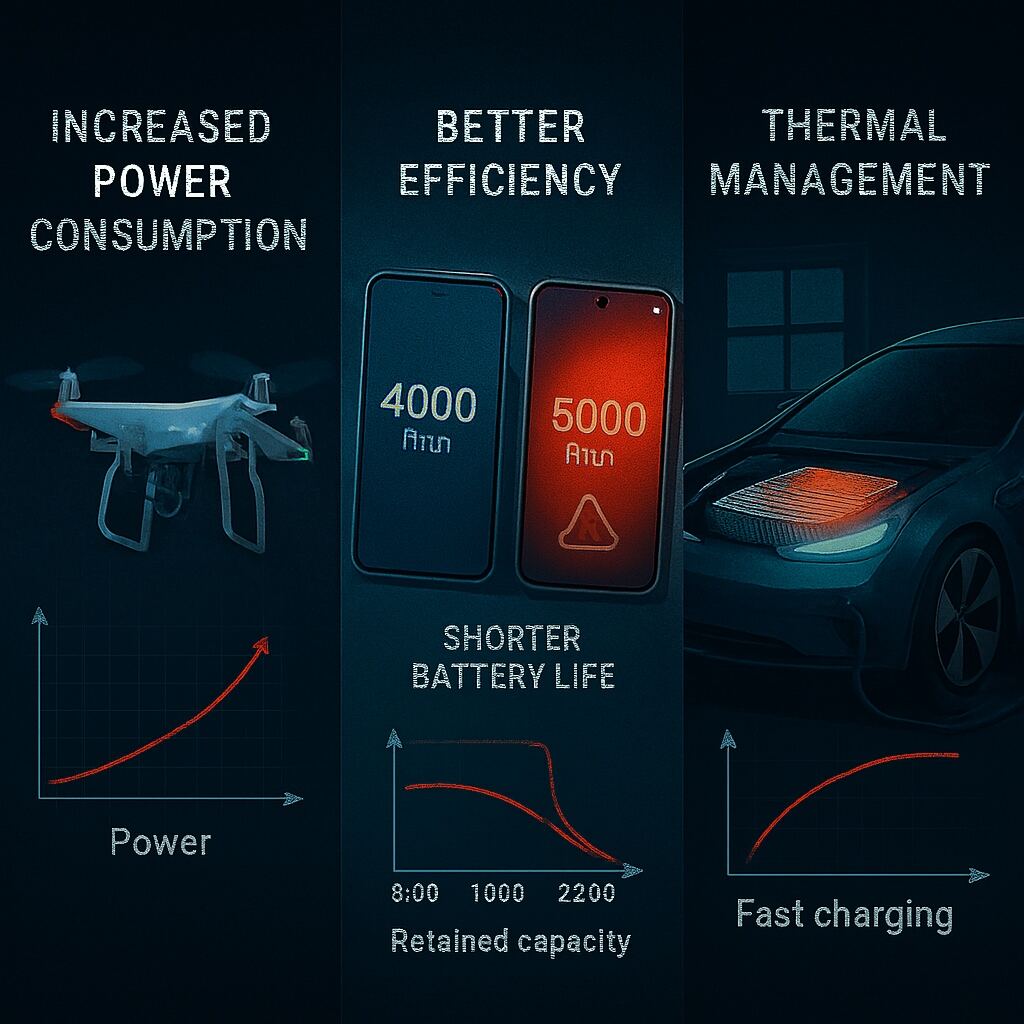

These considerations become especially salient in application-specific contexts. In UAV systems, users often assume that installing a higher-capacity battery will extend flight time. In practice, the added mass may increase power consumption, while high internal resistance may trigger low-voltage protection prematurely, ultimately reducing effective flight duration. This is why professional UAV battery platforms (e.g., MC1, MC3 Elite, Smart-MC) emphasize high discharge capability and thermal robustness in addition to capacity. In smartphones, manufacturers frequently highlight mAh ratings, yet user experience depends more heavily on SoC efficiency, thermal management, and charging algorithms. A well-optimized 4000 mAh device may outperform a poorly managed 5000 mAh competitor in daily use. In electric vehicles, battery quality is evaluated across the entire lifecycle: beyond capacity, factors such as cycle life, thermal management efficiency, fast-charging compatibility, and crash-scenario safety redundancy determine commercial viability and user trust.

6. Market Misrepresentation and Consumer Risk

Unfortunately, the market still contains products that exploit consumers’ preference for large numerical specifications. Some low-cost batteries inflate capacity ratings by testing at extremely low discharge rates, employing permissive cutoff voltages, conflating nominal and typical capacity, or incorporating recycled or low-grade cells. Such practices are common in low-end power banks and drone batteries. A product advertised as “10,000 mAh” may deliver only 5000–6000 mAh in real-world use, misleading consumers and potentially introducing safety risks.

7. Criteria for Evaluating True Battery Quality

Consequently, evaluating whether a battery is genuinely high-quality requires systematic, multidimensional testing. This includes capacity verification at multiple discharge rates, internal resistance measurement, voltage-response characterization, and cycle-life tracking. Thermal evaluation must assess temperature rise under load, thermal-runaway thresholds, and heat-dissipation pathways. Mechanical testing encompasses vibration resistance, drop impact, and sealing integrity. At the pack level, BMS balancing accuracy, protection-logic reliability, and firmware stability must be validated. Only batteries that demonstrate robust performance across these dimensions—and align closely with the requirements of their intended application—can be considered truly high-quality.

8. Conclusion: Beyond Capacity—Toward Holistic Battery Design

In summary, while capacity is an important metric, it is far from sufficient for assessing battery quality. Overemphasizing capacity while neglecting power density, thermal safety, cycle life, and system-level integration can lead to suboptimal or even hazardous outcomes. The ideal battery achieves a carefully engineered balance among energy density, discharge capability, thermal stability, longevity, safety, mechanical durability, and application-specific suitability. For UAVs, robotics, electric vehicles, and advanced electronic systems, engineers and decision-makers must adopt a holistic evaluation framework that transcends simplistic capacity-based comparisons to identify power sources that are genuinely reliable and fit for purpose.