In today's interconnected world, compact electronic devices have become essential components of both consumer electronics and industrial applications. From digital watches and medical devices to remote controls and computer motherboards, these miniature gadgets require reliable, long-lasting power sources that can fit within their constrained spaces. The lithium button cell has emerged as the preferred power solution for countless small-scale electronic applications, offering exceptional energy density, consistent voltage output, and remarkable shelf life that traditional alkaline batteries simply cannot match.

Understanding Lithium Button Cell Technology

Chemical Composition and Energy Storage

The fundamental advantage of lithium button cell technology lies in its sophisticated electrochemical design. These compact power sources utilize lithium metal as the anode material, combined with various cathode compositions such as manganese dioxide, thionyl chloride, or carbon monofluoride. This chemical combination creates an exceptionally high energy density, allowing manufacturers to pack substantial power capacity into remarkably small form factors. The lithium-based chemistry also provides superior voltage stability throughout the discharge cycle, maintaining consistent 3-volt output until near complete depletion.

The electrolyte system within these cells plays a crucial role in their performance characteristics. Organic electrolytes enable operation across wide temperature ranges while preventing the internal corrosion that commonly affects other battery chemistries. This robust construction allows lithium button cells to maintain their rated capacity even after years of storage, making them ideal for devices that may remain dormant for extended periods before activation.

Size Standardization and Compatibility

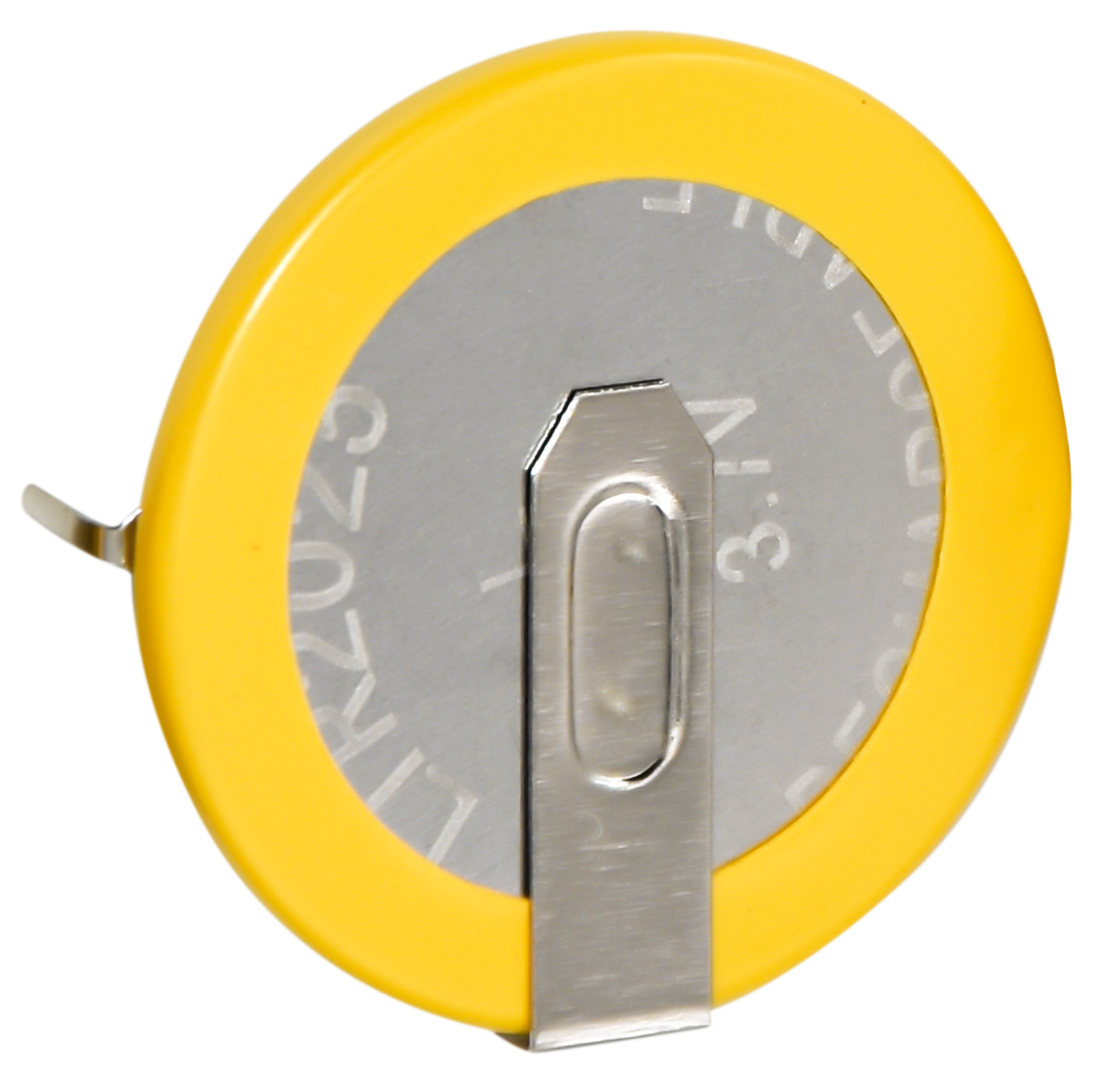

Industry standardization has been essential to the widespread adoption of lithium button cell technology. The International Electrotechnical Commission has established specific dimensional and performance standards that ensure compatibility across different manufacturers and applications. Common sizes like CR2032, CR2025, and CR2016 have become ubiquitous in electronic device design, with the numbering system indicating both diameter and thickness specifications.

This standardization extends beyond physical dimensions to include electrical specifications, terminal configurations, and safety requirements. Manufacturers must adhere to strict quality control processes to ensure their products meet international standards for capacity, discharge characteristics, and operational safety. The result is a reliable supply chain of interchangeable power sources that electronic device designers can confidently specify in their products.

Applications Across Electronic Device Categories

Consumer Electronics Integration

Consumer electronics represent the largest market segment for lithium button cell applications, spanning everything from wearable fitness trackers to smart home sensors. These devices typically require minimal power consumption for basic functions like timekeeping, data storage, or wireless communication, making the lithium button cell an optimal power solution. The compact form factor allows designers to minimize device thickness while maximizing battery life, creating sleeker, more attractive products that consumers demand.

Gaming controllers, remote controls, and digital cameras frequently utilize multiple lithium button cells to provide extended operation periods between replacements. The consistent voltage output ensures reliable performance of sensitive electronic components, while the low self-discharge rate means devices can remain functional even after months of non-use. This reliability has made lithium button cells indispensable for applications where unexpected power failure could result in data loss or device malfunction.

Medical and Healthcare Applications

The medical device industry has embraced lithium button cell technology for applications ranging from glucose monitors to hearing aids and implantable medical devices. These applications demand exceptional reliability and longevity, as battery replacement may be inconvenient, expensive, or potentially dangerous for patients. The superior shelf life and predictable discharge characteristics of lithium chemistry make it possible to design medical devices with multi-year operational lifespans.

Pacemakers and other implantable devices represent perhaps the most critical application of lithium button cell technology. These life-sustaining devices require power sources that can operate reliably for decades within the human body, maintaining consistent performance despite temperature variations and mechanical stress. Advanced lithium cell designs incorporate hermetic sealing and biocompatible materials to ensure patient safety while delivering the electrical performance necessary for proper device operation.

Technical Performance Characteristics

Voltage Stability and Discharge Curves

One of the most significant advantages of lithium button cell technology is its exceptional voltage stability throughout the discharge cycle. Unlike alkaline batteries that exhibit gradually declining voltage output, lithium cells maintain nearly constant 3-volt output until approaching complete depletion. This characteristic is particularly important for digital electronics that require stable voltage references for accurate operation of analog-to-digital converters, precision timing circuits, and memory retention systems.

The flat discharge curve of lithium button cells enables electronic designers to optimize circuit performance without incorporating complex voltage regulation systems. Devices can operate at peak efficiency throughout most of the battery's useful life, maximizing both performance and operational duration. This predictable behavior also simplifies battery life estimation and replacement scheduling in critical applications.

Temperature Performance and Environmental Resilience

Environmental operating conditions significantly impact battery performance, making temperature resilience a crucial consideration for many applications. Lithium button cells demonstrate superior performance across wide temperature ranges, typically maintaining acceptable capacity from -20°C to +60°C or beyond. This temperature stability stems from the electrochemical properties of lithium metal and organic electrolyte systems that resist freezing and maintain ionic conductivity across varied conditions.

Industrial and outdoor applications particularly benefit from this temperature resilience. Security sensors, weather monitoring equipment, and automotive electronics must continue functioning despite extreme environmental conditions that would severely degrade the performance of alternative battery technologies. The robust construction and stable chemistry of lithium button cells ensure reliable operation in these demanding environments.

Manufacturing and Quality Control Standards

Production Process Optimization

Modern lithium button cell manufacturing involves sophisticated automated processes designed to ensure consistent quality and performance across millions of units. Production begins with precision forming of metallic housings, followed by careful assembly of electrode materials and electrolyte systems under controlled atmospheric conditions. Automated equipment handles the delicate process of sealing each cell while maintaining the precise internal pressure necessary for optimal performance.

Quality control throughout the manufacturing process involves multiple testing stages, from raw material verification to final product validation. Each production batch undergoes electrical testing to verify capacity, voltage output, and discharge characteristics meet specified requirements. Environmental stress testing ensures cells can withstand temperature cycling, humidity exposure, and mechanical vibration that may occur during shipping and end-use applications.

Safety Testing and Certification Requirements

International safety standards govern lithium button cell production and distribution, requiring extensive testing to verify compliance with transportation, handling, and operational safety requirements. These standards address potential hazards associated with lithium metal reactivity, including tests for short circuit resistance, overheating protection, and mechanical abuse tolerance. Manufacturers must demonstrate their products meet these rigorous standards before receiving certification for commercial distribution.

Certification processes typically involve third-party testing laboratories that verify compliance with relevant standards such as UL 1642, IEC 62133, and UN 38.3. These comprehensive testing programs evaluate battery performance under various abuse conditions, ensuring consumer safety while maintaining the high performance characteristics that make lithium button cells attractive for electronic device applications.

Future Developments and Emerging Technologies

Advanced Chemistry Innovations

Research and development efforts continue to push the boundaries of lithium button cell technology, focusing on increased energy density, extended operational life, and enhanced environmental compatibility. New cathode materials and electrolyte formulations promise to deliver higher capacity in existing form factors while maintaining the voltage stability and longevity that characterize current lithium cell technology. These advances will enable more sophisticated electronic devices with extended operational periods between battery replacements.

Solid-state electrolyte systems represent a particularly promising development direction, potentially eliminating liquid electrolytes that can leak or degrade over time. Solid-state designs could also enable operation at higher temperatures and provide improved safety characteristics, expanding the range of applications where lithium button cells can be successfully deployed. These technological advances will likely drive continued growth in compact electronic device markets.

Integration with Smart Device Ecosystems

The proliferation of Internet of Things devices and smart sensor networks is creating new demands for power sources that can support wireless communication capabilities while maintaining ultra-low power consumption during standby periods. Future lithium button cell designs may incorporate intelligent power management features, allowing devices to optimize energy usage based on operational requirements and remaining battery capacity.

Integration with energy harvesting technologies could extend operational lifespans even further, with ambient light, thermal gradients, or mechanical vibration supplementing stored chemical energy. These hybrid power systems would combine the reliability and energy density of lithium chemistry with renewable energy sources, creating truly long-term autonomous electronic devices suitable for remote monitoring and sensing applications.

FAQ

How long do lithium button cells typically last in electronic devices

The operational lifespan of lithium button cells varies significantly based on device power consumption, operating temperature, and usage patterns. In low-power applications like digital watches or memory backup circuits, high-quality lithium button cells can provide reliable operation for 5-10 years or more. Higher-drain devices such as LED flashlights or wireless transmitters may consume battery capacity within months to a few years, depending on usage intensity and circuit efficiency.

Can lithium button cells be recharged or are they single-use only

Standard lithium button cells are designed as primary batteries for single-use applications and should never be recharged. Attempting to recharge primary lithium cells can result in dangerous overheating, electrolyte leakage, or even fire and explosion hazards. However, specialized rechargeable lithium button cells are available for applications specifically designed to accommodate charging systems, though these typically offer lower capacity and shorter cycle life compared to primary lithium cells.

What safety precautions should be observed when handling lithium button cells

Proper handling of lithium button cells requires awareness of potential hazards associated with lithium metal reactivity and electrical energy storage. Never disassemble cells or expose them to excessive heat, moisture, or mechanical damage. Store batteries in cool, dry conditions away from conductive materials that could cause short circuits. When disposing of used cells, follow local regulations for hazardous waste disposal, as lithium and other cell components require specialized recycling processes.

How do environmental conditions affect lithium button cell performance

Environmental factors significantly influence lithium button cell performance and operational lifespan. Extreme temperatures can reduce available capacity and affect discharge characteristics, with both very cold and very hot conditions potentially limiting battery effectiveness. High humidity environments may contribute to external corrosion of battery terminals, while mechanical vibration or shock could damage internal cell structures. For optimal performance, lithium button cells should be used within manufacturer-specified temperature ranges and protected from environmental extremes when possible.