Abstract

Swelling in lithium-based batteries used in unmanned aerial vehicles (UAVs) is a critical degradation phenomenon that directly affects operational reliability and safety. This paper provides an expanded and systematic examination of the physicochemical mechanisms responsible for swelling, differentiates between operational and storage-related swelling behaviors, evaluates associated hazards, and proposes evidence-based preventive strategies. By integrating electrochemical theory with UAV-specific usage patterns, this study aims to support safer drone operation and inform future improvements in battery management systems (BMS).

1. Introduction

Lithium-ion (Li-ion) and lithium-polymer (LiPo) batteries have become the dominant power sources for UAVs due to their high energy density, lightweight structure, and stable discharge characteristics. As UAV applications expand into fields such as aerial mapping, precision agriculture, emergency response, and industrial inspection, the reliability of onboard power systems has become increasingly important.

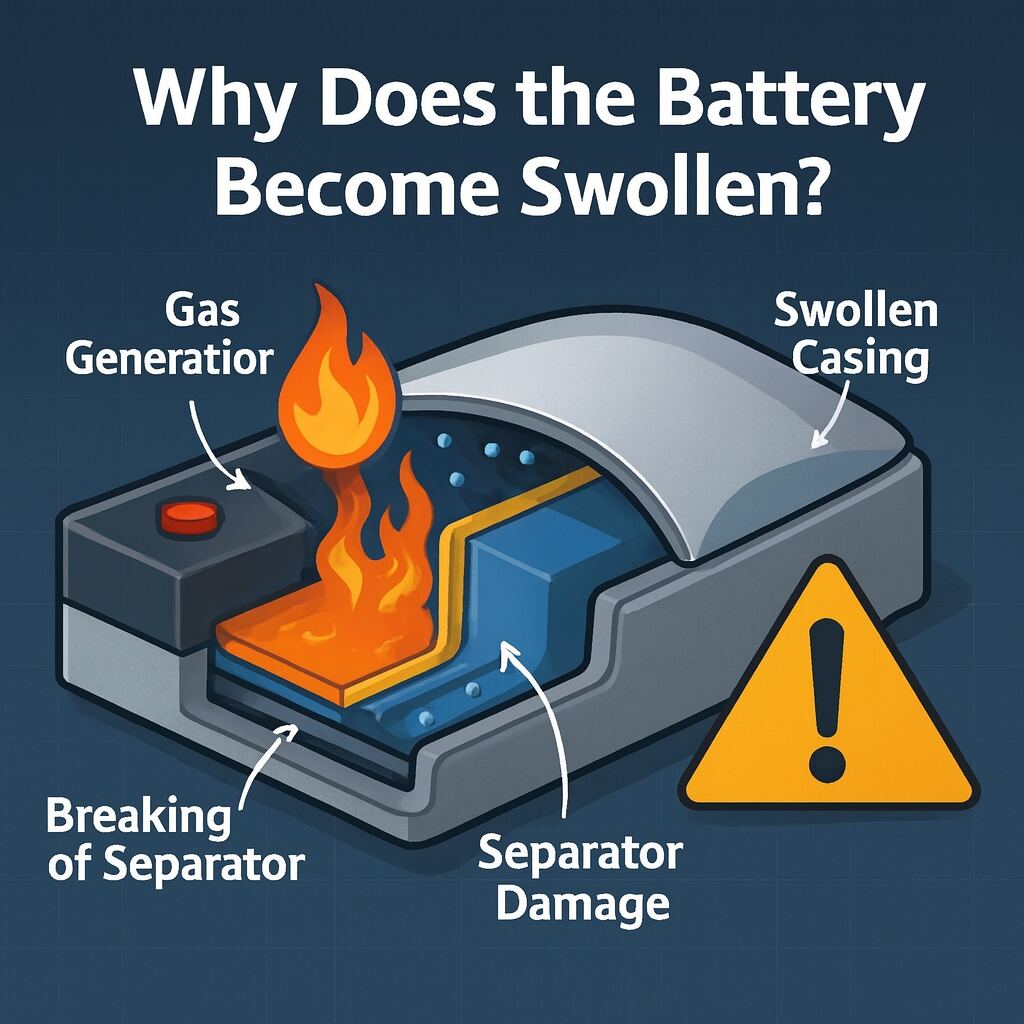

Despite their advantages, lithium-based batteries are susceptible to degradation when exposed to thermal stress, mechanical impact, improper charging, or unsuitable storage conditions. Among the various degradation modes, battery swelling—characterized by abnormal expansion of the cell pouch or casing—has emerged as a major safety concern. Swelling not only reduces battery performance but also increases the risk of fire, rupture, and toxic gas release.

This paper expands upon existing research by providing a detailed analysis of swelling mechanisms, contributing factors, and preventive measures tailored to UAV operational environments.

2. Classification of Battery Swelling Phenomena

2.1 Transient Swelling During High-Load Operation

During demanding flight missions, UAV batteries may experience rapid temperature increases due to high discharge currents. Activities such as rapid acceleration, strong-wind hovering, or carrying heavy payloads significantly increase internal resistance heating.

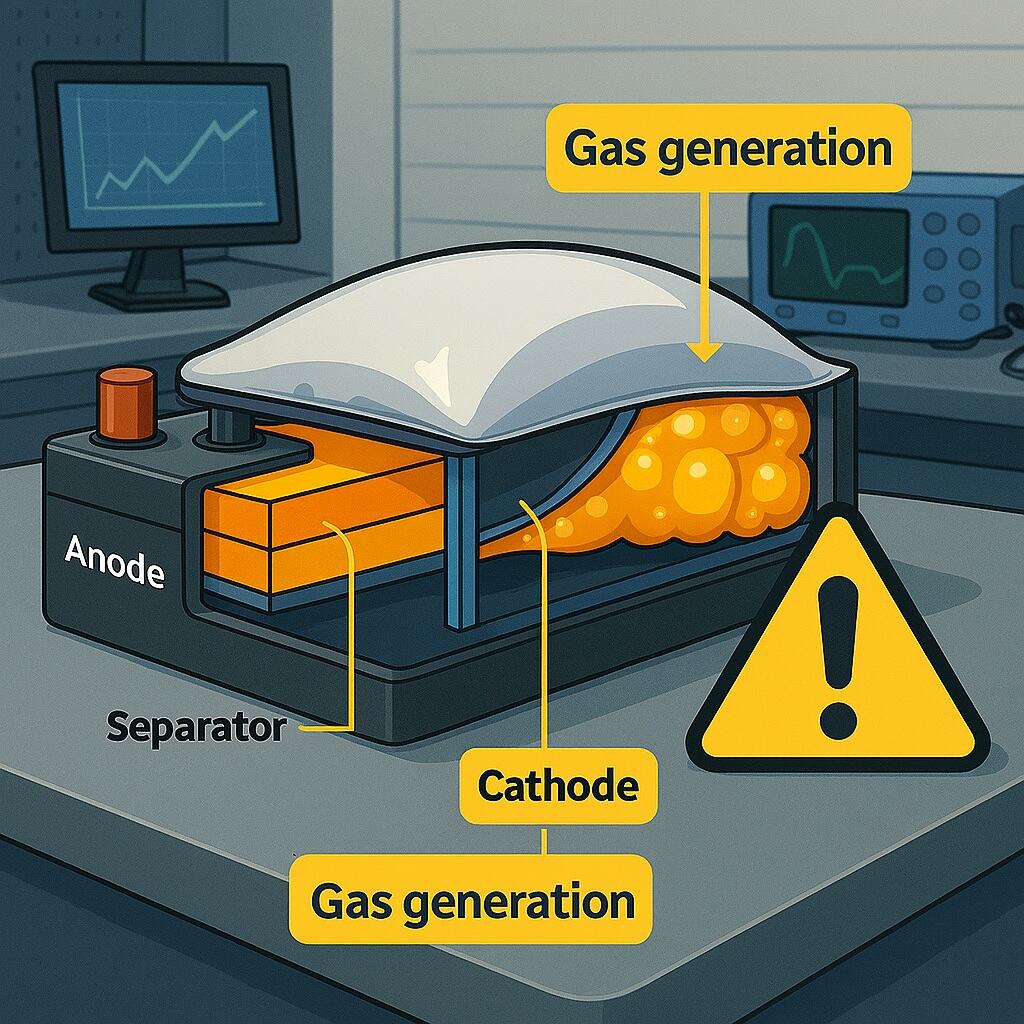

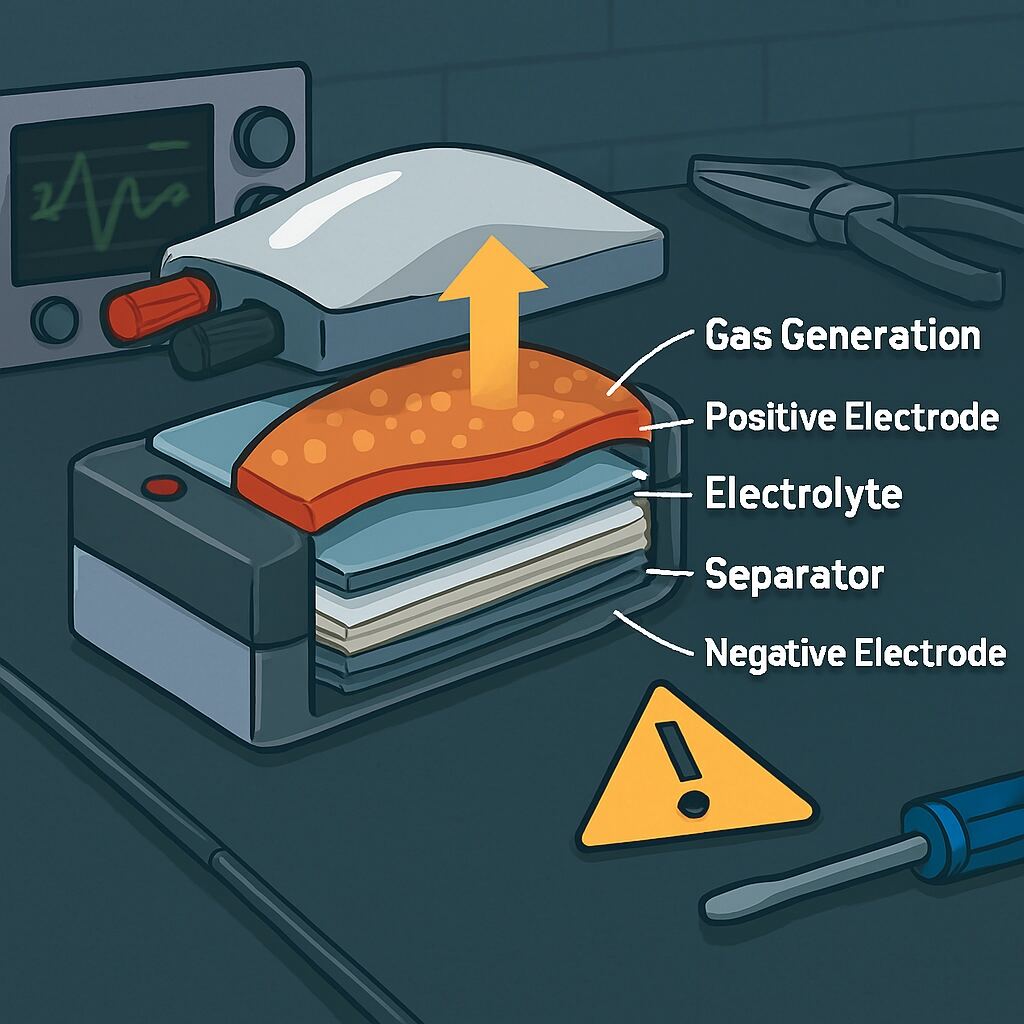

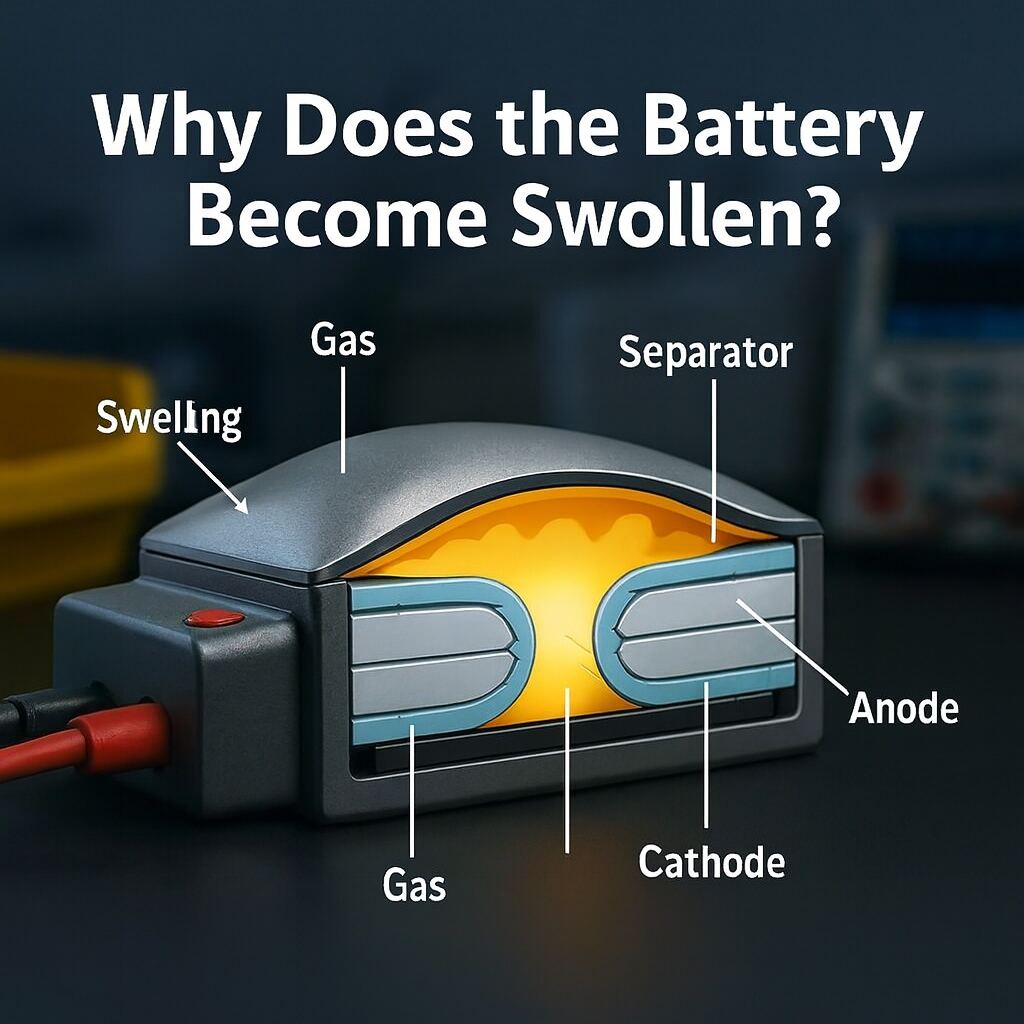

When the cell temperature exceeds the recommended operational threshold (typically above 40–45°C), parasitic reactions begin to occur. These reactions include partial decomposition of electrolyte solvents and destabilization of the solid electrolyte interphase (SEI). The resulting gaseous byproducts—commonly CO₂, H₂, and low-molecular-weight hydrocarbons—accumulate inside the sealed battery enclosure.

This form of swelling is generally reversible. Once the battery cools, internal pressure decreases and the casing may return to its original shape. However, repeated exposure to high temperatures accelerates SEI breakdown, increases internal resistance, and promotes long-term degradation. Over time, transient swelling may evolve into irreversible swelling if thermal stress persists.

2.2 Irreversible Swelling During Storage

Swelling that occurs during storage is typically more severe and indicates permanent internal damage. Unlike operational swelling, which is often temperature-driven, storage-related swelling is primarily associated with electrochemical instability and long-term degradation.

2.2.1 Cycle-Induced Aging

Lithium-based batteries undergo structural and chemical changes with each charge-discharge cycle. Over hundreds of cycles, the SEI layer thickens, active material becomes isolated, and electrode porosity decreases. These changes increase internal resistance and promote gas-forming reactions.

As the battery approaches the end of its useful life, even minor stressors—such as slight overcharge or mild temperature fluctuations—can trigger swelling.

2.2.2 Improper Storage Conditions

Several storage-related factors significantly increase swelling risk:

● Deep discharge (<3.0 V per cell) may cause copper dissolution from the anode current collector, leading to internal short circuits.

● Mechanical damage can compromise the separator, enabling direct electrode contact.

● Moisture ingress reacts with electrolyte components, generating heat and gas.

● Extreme state-of-charge storage accelerates electrolyte oxidation and SEI instability.

● High-temperature storage (30°C) increases reaction rates and gas formation.

These factors collectively contribute to irreversible swelling, often accompanied by capacity loss and voltage instability.

3. Physicochemical Mechanisms of Swelling

3.1 Electrolyte Decomposition

Organic carbonate-based electrolytes are thermally sensitive. When exposed to high temperatures or overvoltage conditions, they decompose into gaseous byproducts. This decomposition is one of the primary contributors to swelling.

3.2 Lithium Plating and Dendrite Formation

Charging at low temperatures or high voltages can cause metallic lithium to deposit on the anode surface. Lithium plating reduces capacity and increases internal resistance. More critically, metallic lithium is highly reactive and can initiate gas-forming reactions with electrolyte solvents.

3.3 SEI Layer Instability

The SEI layer is essential for stabilizing the anode-electrolyte interface. However, thermal stress, overcharging, or mechanical deformation can cause SEI cracking. Repeated SEI breakdown consumes electrolyte and generates gas, contributing to swelling.

3.4 Separator Degradation

The separator is a porous polymer membrane that prevents direct contact between electrodes. Mechanical impact, overheating, or manufacturing defects may weaken the separator. Once compromised, internal short circuits can occur, leading to rapid heat generation and gas evolution.

4. Identification and Evaluation of Swollen Batteries

Early detection of swelling is crucial for preventing accidents. Key indicators include:

● Visible deformation or expansion of the battery casing

● Difficulty inserting or removing the battery from the UAV

● Sweet or pungent chemical odors

● Reduced flight time or unstable voltage output

● Elevated temperature during charging or discharging

Swollen batteries must be removed from service immediately. Attempts to puncture or compress the battery to release internal pressure are extremely dangerous and may trigger ignition.

5. Safety Risks Associated With Swelling

5.1 Fire and Thermal Runaway

Internal short circuits or exothermic reactions may trigger thermal runaway, a self-accelerating process that can lead to fire.

5.2 Mechanical Rupture

Excessive internal pressure may cause the battery casing to rupture, releasing hot gases and flammable electrolyte.

5.3 Toxic Gas Emission

Electrolyte decomposition products may include harmful organic vapors that pose respiratory hazards.

5.4 UAV Structural Damage

A swollen battery may deform the UAV’s battery compartment, damage connectors, or interfere with cooling systems.

6. Preventive Strategies

6.1 Charging Management

● Use manufacturer-approved chargers and avoid fast charging unless explicitly supported.

● Do not leave batteries unattended during charging.

● Stop charging once full and periodically balance cell voltages.

● Avoid charging immediately after flight; allow adequate cooling time.

6.2 Thermal Control

● Store batteries in cool, dry environments.

● Avoid exposing UAVs to direct sunlight for extended periods.

● Use fire-resistant or thermally insulated containers during transport.

6.3 Storage Optimization

● Maintain a 40–60% state of charge for long-term storage.

● Recharge every 1–3 months to prevent deep discharge.

● Store batteries individually to prevent thermal propagation.

6.4 Mechanical Protection

● Avoid dropping or compressing the battery.

● Protect against moisture and vibration.

● Inspect regularly for signs of wear or deformation.

6.5 Operational Monitoring

● Track cycle count and performance metrics via flight control systems.

● Replace batteries showing abnormal voltage behavior or capacity decline.

● Keep firmware updated to benefit from improved battery management algorithms.

7. Conclusion

Battery swelling in UAV systems is a multifactorial phenomenon driven by thermal stress, electrochemical degradation, mechanical damage, and improper storage practices. While transient swelling during operation may be reversible, swelling observed during storage typically reflects irreversible internal failure.

By adopting scientifically grounded charging, storage, and monitoring practices, users can significantly reduce swelling incidence and enhance UAV safety. Although advances in battery chemistry and management systems will continue to improve reliability, user awareness remains a critical factor in preventing swelling-related hazards.